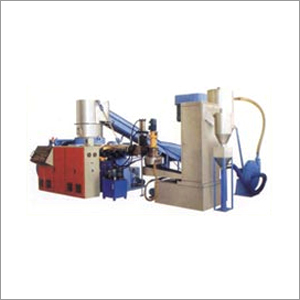

Pelletizing Line With Crusher

Pelletizing Line With Crusher Specification

- Material

- SS

- Computerized

- No

- Automatic Grade

- Automatic

- Control System

- PLC Control

- Voltage

- 220-440 Volt (v)

- Warranty

- 1 Year

Pelletizing Line With Crusher Trade Information

- Minimum Order Quantity

- 1 Unit

- Delivery Time

- 15-20 Days

About Pelletizing Line With Crusher

We are a prime manufacturer and exporter of an astounding reach ofPelletizing Line With Crusher.The offered hardware is made with high-review component include as per the business standards. Our quality controller analyzes this hardware on distinctive parameters so as to guarantee its execution. Additionally, we offer this hardware in various particulars in order to satisfy the needs of benefactors. Our array of Pelletizing Line With Crusher is very much acclaimed for features like simple to keep up, high usefulness, accurately built, and so forth.

Durable Stainless Steel Construction

Fabricated from high-grade stainless steel, the pelletizing line ensures corrosion resistance, prolonged service life, and dependable operation in demanding environments. Its robust design makes it suitable for various industries seeking long-term productivity.

Seamless Automatic Operation

Featuring an automatic setup paired with a sophisticated PLC control system, this pelletizing line offers user-friendly functionality. The automation helps maintain high throughput with minimal manual intervention, thereby streamlining your production process.

Versatile Voltage Compatibility

Operating across a wide voltage range of 220-440V, this equipment fits seamlessly into different industrial electrical setups. Its flexibility allows for easy integration, regardless of your facilitys power requirements.

FAQs of Pelletizing Line With Crusher:

Q: How does the Pelletizing Line With Crusher operate?

A: The pelletizing line functions automatically using a PLC control system to manage the entire process, from material crushing to pellet formation, ensuring consistent output and reduced manual handling.Q: What materials can be processed with this machine?

A: Designed with sturdy stainless steel construction, the pelletizing line is suitable for processing a wide range of raw materials, including polymers, plastics, or similar feedstocks that require size reduction and pelletization.Q: When is routine maintenance required for this equipment?

A: Regular maintenance is suggested at least every six months or as specified in the user manual, to prolong the machines life and ensure trouble-free operation. The stainless steel build reduces the overall frequency of required maintenance.Q: Where is this pelletizing line manufactured and supplied from?

A: This equipment is proudly designed, manufactured, and supplied from India and is available for export to global markets through our established distribution network.Q: What is the process flow within the pelletizing line?

A: Raw material enters the crusher unit for size reduction, followed by automatic conveyance to the pelletizer, where it is processed into uniform pellets. The integrated PLC system synchronizes the process for optimal productivity.Q: How is the machine controlled during operation?

A: Operations are managed through a user-friendly PLC (Programmable Logic Controller) system, providing reliable control over critical machine parameters and ensuring a steady and safe workflow.Q: What are the key benefits of using this pelletizing line?

A: The main advantages include high efficiency, low manual intervention due to automation, superior durability from stainless steel components, wide voltage compatibility, and peace of mind with a one-year warranty.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pelletizing Line Category

Plastic Pelletizing Line

Minimum Order Quantity : 1 Unit

Control System : Human Machine Interface

Automatic Grade : Automatic

Drive Type : Electric

Warranty : 1 Year

Voltage : 220440 Volt (v)