Drip Irrigation Pipe Production Line

Drip Irrigation Pipe Production Line Specification

- Material

- MS

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- PLC Control

- Drive Type

- Hydraulic

- Warranty

- 1 Year

Drip Irrigation Pipe Production Line Trade Information

- Minimum Order Quantity

- 1 Unit

- Delivery Time

- 15-20 Days

About Drip Irrigation Pipe Production Line

Inline Drip Irrigation Systems which is at par with required industry standards and norms. This irrigation system is basically a wide network of pipes and tubes, which waters the crops and plants without wasting water and optimizes crop production without straining.Advanced Automation for Consistency

Experience seamless, consistent production with our fully automatic drip irrigation pipe line. Automated controls not only reduce manual intervention but also enhance output quality and efficiency, crucial in high-volume operations.

Robust and Reliable Build

Manufactured from durable mild steel (MS), our production line ensures long-lasting performance even in demanding industrial settings. The hydraulic drive system guarantees smooth operation and reduced maintenance requirements, resulting in less downtime.

Intelligent Control and Easy Operation

Featuring sophisticated PLC control, the system offers simple programming and real-time monitoring for every phase of the manufacturing process. This enables operators to quickly adjust parameters and maintain stringent quality standards.

FAQs of Drip Irrigation Pipe Production Line:

Q: How does the automatic drip irrigation pipe production line operate?

A: The production line functions automatically using a hydraulic drive system and is managed through a PLC control unit. This allows for consistent production with minimal manual input, ensuring high accuracy and repeatability.Q: What materials are used in the construction of the machine?

A: The production line is constructed with MS (Mild Steel), providing a strong and sturdy framework that ensures durability as well as reliable performance over extended periods of use.Q: When is the ideal time to invest in this production line?

A: Investing in this line is suitable when aiming to enhance productivity, improve pipe quality, or expand manufacturing capacity, especially if you plan to meet large-scale demands efficiently.Q: Where can the drip irrigation pipe production line be installed?

A: The unit can be set up in any manufacturing facility with sufficient space and infrastructure, both within India and internationally, as we export to various regions.Q: What is the process involved in manufacturing drip irrigation pipes using this line?

A: The process includes feeding raw materials, extrusion of pipes, cooling, cutting, and coiling, all managed automatically by the PLC and supported by the hydraulic drive system for seamless transitions.Q: How is the production line controlled and monitored?

A: The system relies on a PLC (Programmable Logic Controller) control panel, allowing operators to program, adjust, and monitor operations in real time, ensuring optimal efficiency and minimal errors.Q: What benefits does this production line offer to manufacturers?

A: Benefits include higher production efficiency, reduced manual labor, improved product quality, and reliable after-sales support through a 1-year warranty. These features collectively assist manufacturers in maintaining a competitive edge.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Drip Irrigation Pipe Production Line Category

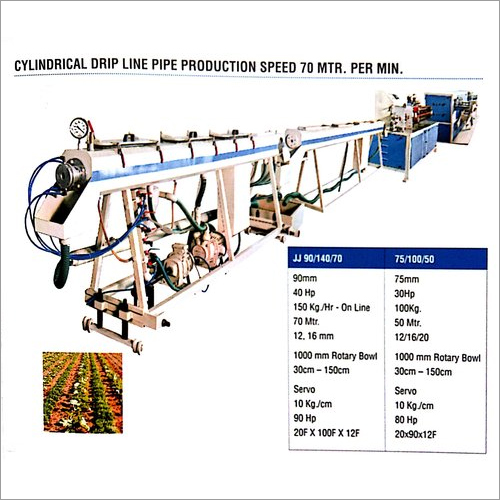

Cylindrical Drip Line Pipe Production Speed 70 MTR

Computerized : Yes

Material : Stainless Steel, Alloy Steel

Voltage : 380 V

Control System : Other, PLC Controlled

Drive Type : Electric

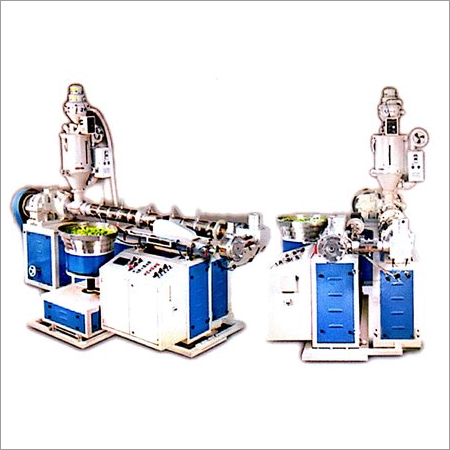

Cylindrical Drip Line

Computerized : Yes

Material : High Quality Polyethylene (PE)

Voltage : 380V/220V, 50Hz/60Hz

Control System : Other, PLC Controlled

Drive Type : Electric

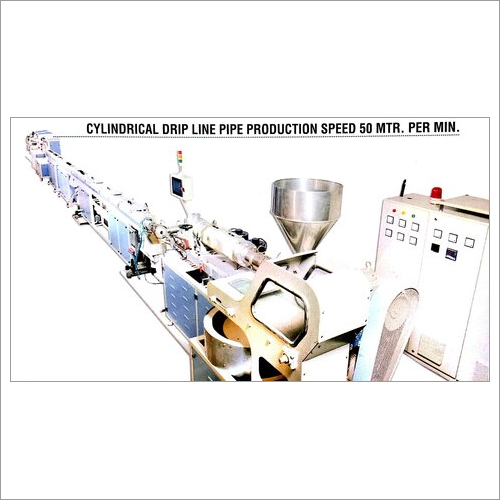

Cylindrical Drip Line Pipe Production Speed 50 MTR

Computerized : Yes

Material : High Quality Polyethylene (PE)

Voltage : 380V / 50Hz

Control System : PLC Control

Drive Type : Electric

Round Drip Irrigation Pipe Production Line

Minimum Order Quantity : 1 Unit

Computerized : No

Material : SS

Voltage : 220440 Volt (v)

Control System : Human Machine Interface

Drive Type : Electric